X-ray diffraction is a little known technique, which allows the detection of residual stress and the assessment of the amount of retained austenite in mechanical samples.

Residual stress is caused by heat treatments, mechanical treatments, welding and surface treatments the components underwent during their production process.

This stress critically influences the endurance, especially the fatigue endurance, of the components and it is often the cause of damages that have no metallurgic reasons.

Alterations of surface stress caused by grinding burns, which are easily detectable through x-ray diffraction or through Barkhausen Noise analysis are a good example.

As far as retained austenite is concerned, its presence, even in small percentages (5%), may cause deformations that can make the component useless. For example, in ball bearing tracks and injector pins in diesel engines. Detecting its presence allows the optimization of heat treatments.

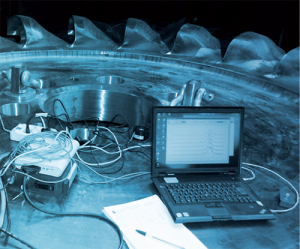

In order to measure residual stress and to detect retained austenite, 2 Effe Engineering uses instruments that permit a completely non-destructive analysis of samples of any size and allow the on-field detection, as well. Eng. Marconi, for example, measured the residual stress, caused by melting and mechanical treatments, on the cable terminals of Störebealt bridge in Denmark.

The main applications of x-ray diffraction technique are:

- measurement of retained austenite on bearings and injector components of diesel engines

- detection of residual stress on gear wheels

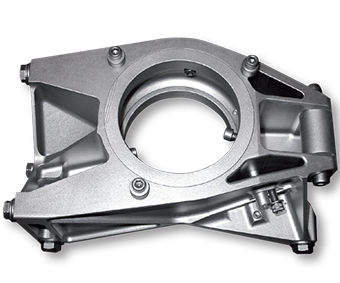

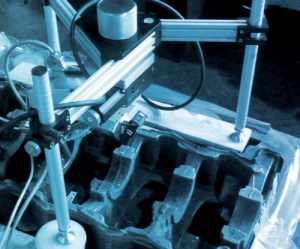

- detection of residual stress on automobile engine components (camshafts, piston rods, drive shafts, balance wheels)

- detection of residual stress caused by deep-drawings (household products and structure components)

- detection of stress in operation on gas pipes

- detection of stress in operation on big tensile structures

- detection of effectiveness of shot peening and rolling treatments on components exposed to fatigue

- detection of residual stress in castings (cast iron machine tool components and automotive aluminium castings)

- detection of stress caused by welding (laser welding and electron beam welding)

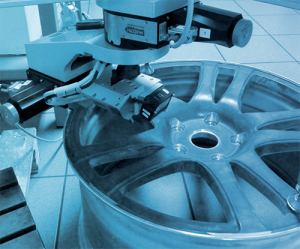

- research of a connection between residual stress and fatigue endurance of car rims made of aluminium alloy

- optimization of working parameters for swarf removal in order to improve fatigue endurance in mechanical components

- detection of residual stress in both helical and leaf springs

- research of critical areas due to the application of working loads (weapon and aerospace industries)

A particular application of XRD technology is the quantitative detection of the presence of different crystalline phases of materials, thanks to a bigger spectrum of analysis.

In some cases, the identification of the crystalline phases of the material is very important because they may influence, sometimes considerably, its functional characteristics.

This technique allows 2 Effe Engineering to verify the correct composition of HVOF coatings.