2 Effe Engineering has developed a polishing system with diamond pastes, which allows to obtain a very low level of roughness (Ra<0,02 µm).

This operation acts superficially, thus creating high degrees of compression (>-900Mpa).

Our polishing system eliminates roughness crests without using acids, which could cause, over the years, corrosion phenomena.

Not only do the morphologic characteristics of a surface considerably influence the fatigue behaviour of mechanical components, but the surface state also influences functional characteristics such as efficiency of the lubricant film and fluid-dynamic performances.

In order to improve the performance of some mechanical components, their surface finishing plays a role of great importance.

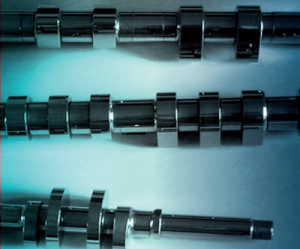

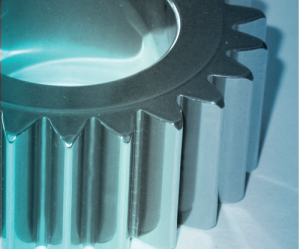

Lapping operations allow to obtain a surface finishing characterized by isotropicity and low level of roughness, less than 0,02 Ra, on components with a notably complex geometry, such as gear wheels, drive shaft and camshafts, turbine blades and valve components.

The process consists, essentially, in a mechanical removal of the working (generally grinding) crests, through abrasive paste spread in water solution.

It does not cause significant geometric deformation and, depending on the starting roughness, crest removal might be of microns fractions.

2Effe Engineering can:

- detect stress caused by polishing, using X-ray diffraction;

- evaluate, through scanning electron microscopes (SME), the morphology of the polished surface;

- carry out a quality chemical analysis of particles that might be laid on the surface, using a micro analysis probe.

Upon request by the customer, the Company can carry out these tests, randomly, on production.