Besides the detection of residual stress through X-ray diffraction, our laboratory can offer a variety of highly technological analysis methods rarely provided for in traditional laboratories.

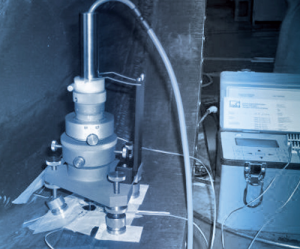

Remaining in the field of residual stress, with the “hole drilling” method, according to specification ASTM E 837, we can perform very deep detections (up to about 2 mm) on big size products on the premises.

The use of scanning electron microscope (SEM) on fracture surfaces allows the detection of fatigue crack activation points; the analysis of the fatigue propagation lines can be a very useful instrument to understand crack propagation.

EDS microprobe allows the basic chemical analysis of inclusions or small metal particles, useful for example to determine their origins.

X-ray diffractometry permits to identify the crystalline phases in the analysed sample, and in some cases, it allows the assessment of the origin of the compounds detected in the sample. As far as crystalline phases of the sample are concerned, we can, for example, evaluate at what temperature they originated.

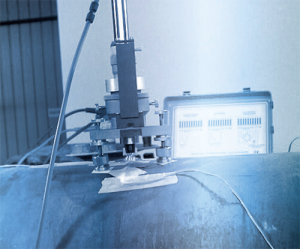

Applied stress, static and dynamic, is also detectable through the use of strain gauges; vibration modes are detectable through accelerometers.

In order to detect grinding burns, 2 Effe Engineering uses the Barkhausen Noise detection technique.

Tools:

-

XDR diffractometer for powders;

-

Scanning Electron Microscope (SEM);

-

EDS microprobe;

-

Hole Drilling Machine;

-

Strain gauge and accelerometer control unit;